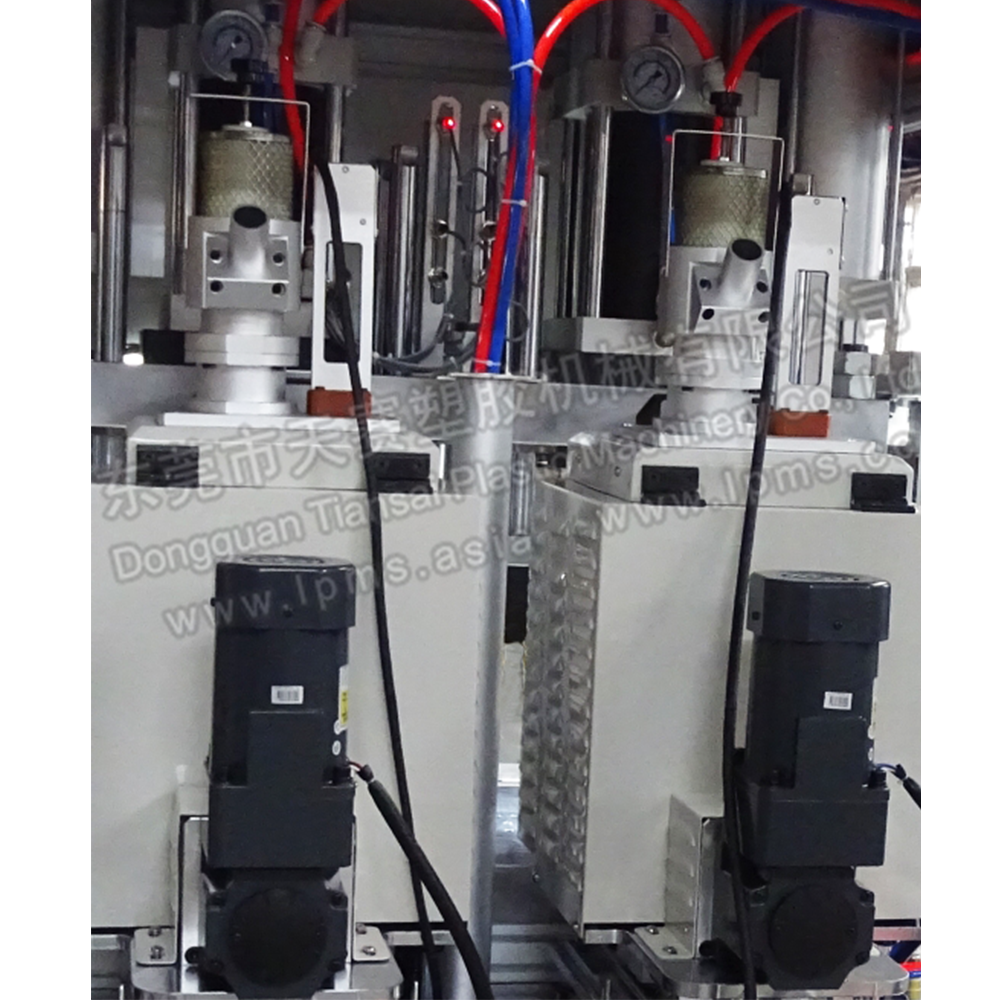

7 liters melting tank is integrated into the machine.

Side injection suitable for multiple cavity and large size part molding. Flexible from simple tools to complicated tools with slide blocks.

Dual tank is more stable and improves the productivity.

Melt-on-demand tank melts the resin within 18 minutes.

Air over oil cylinder gives larger clamp force for larger part.

Key components adopt modular design, easy for maintenance and change.

Four temperature control zones work independently. Over temperature alarm, automatic heating are included.

Two palm buttons and light curtain to protect the operator.

Ejection system is equipped.

Application

LPMS? machines are engineered for low pressure molding, using specialty resins to encapsulate delicate parts, like automotive electronics, PCBA, coil, fiber-optic, LED lighting, cable, etc.

The benefits of side injection is that when one large cavity being encapsulated from the center of the mold, which can prevent the gate mark from the center of product.

Specification

Machine Size / Weight | 40.5 in x 45.28 in x 77.17 in / 1366 lbs |

Footprint | 40.5 in x 45.28 in |

Working Station Height | 850 mm | 33.47 in |

Packing Size / Weight | 44.49 in x 49.21 in x 81.10 in / 1455 lbs |

Melting Tank Model & Q'ty | LPMS-MOD-07-2200H-DSAF1 x2 |

Auto Feeding System | LPMS D10 |

Gun Model & Tip | LPMS-LG02 x 2 / 36.4° |

Heated Hose Model & Q'ty | N/A |

Electricity | 200-240VAC / 1Phase / 50 or 60Hz |

Temperature Control Zones | 4 |

Temperature Range | Ambient up to 250℃ |

Max .Power | 10 kw |

Min. Air Pressure | 0.5 Mpa |

Air Consumption | 0.18 m3 / min |

Clamping | Air Over Oil Cylinder |

Clamping Force | 10 T |

Clamping Stroke | 150 mm |

Control System | PLC+7 in HMI |

Safety device | Light Curtain |

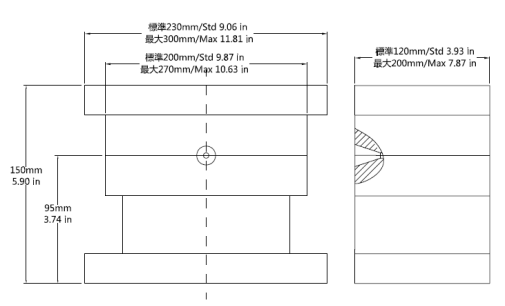

Mold Set Size | 9.06 in x 4.72 in x5.91 in / 55 lbs |

Max . Mold Set Size | 11.81 in x 7.87 in x 5.90 in |

Max . Part Size | 2.36 in x 1.97 in x 0.71 in |

Dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.